Volume 1, Chapter 14 - Material Assets and Waste

Summary

This chapter considers the potential environmental effects of the A9 Dualling Pass of Birnam to Tay Crossing (hereafter referred to as the ‘proposed scheme’) on material assets and waste within the proposed scheme’s boundary (first study area), and Tayside, Central and Fife Local Authority Region (second study area) during the construction of the proposed scheme. Operational effects on material assets and waste have been scoped out of this assessment for the reasons described in paragraphs 14.2.39 and 14.2.40.

The construction of the proposed scheme will unavoidably require the consumption and use of material assets including primary materials and manufactured construction products, and therefore may result in potential effects on the environment through the depletion of non-renewable natural resources. The construction of the proposed scheme will also result in the production and disposal of surplus materials and waste, leading to potential effects on the available waste management infrastructure (i.e. available landfill capacity).

There is likely to be a good supply of both primary and recycled aggregates within the study area to construct the proposed scheme; and there are no minerals safeguarding sites or peat resources within or in close proximity to the first study area. Although the second study area is expected to have sufficient inert landfill capacity to handle most of the surplus materials and wastes generated during the anticipated construction programme (2028 to 2032), there is likely to be limited landfill capacity for both non-hazardous and hazardous wastes.

Throughout the design process, a number of embedded mitigation features have been included in the proposed scheme design with the potential to reduce the consumption and use of material assets and the production and disposal of waste. Where potential residual effects have been identified, these will be reduced, where practicable, during detailed design and construction stage efficiencies and via compliance with relevant legislation, policies and plans relating to the consumption and use of material assets and the management of waste.

With good practice application of responsible sourcing methods, the waste hierarchy, implementation of Site Waste Management Plans and inclusion of targets that support the delivery of the Zero Waste Plan (Scottish Government, 2010) targets, the potential for environmental effects relating to the consumption and use of material assets and production and disposal of waste have been assessed as Slight Adverse (not-significant) and Moderate Adverse (Significant) respectively after the application of essential mitigation measures.

Significant environmental effects are anticipated due to the proposed scheme’s potential use of the available non-hazardous landfill capacity within the second study area, as well as the use of non-hazardous landfill capacity outwith the second study area. Waste transportation beyond the second study area will likely be necessary due to a forecasted lack of non-hazardous landfill capacity by the start of construction of the proposed scheme in 2028. After 2028, non-hazardous landfill options are likely to be limited to sites in Airdrie, Aberdeenshire and Fort William (i.e. unless additional capacity or landfills are commissioned).

Introduction

This chapter presents the results of the material assets and waste assessment undertaken as part of the Design Manual for Roads and Bridges (DMRB) Stage 3 Environmental Impact Assessment Report (EIAR) for the A9 Dualling: Pass of Birnam to Tay Crossing project (hereafter referred to as the ‘proposed scheme’), which is described in Chapter 6 (The Proposed Scheme).

This includes the assessment of potential environmental effects related to the consumption and use of material assets and the production and disposal of waste that can reasonably be anticipated with the construction of the proposed scheme. It identifies measures for mitigating these effects, where practicable, and describes the significance of the residual effects that remain after both embedded and essential mitigation. Operational effects on material assets and waste have been scoped out of this assessment for the reasons described in paragraphs 14.2.39 and 14.2.40.

The assessment is supported by the following appendices and figures presented in Volume 2 and Volume 3 respectively of this EIAR:

- Appendix 14.1 (Assessment of Regulatory and Policy Compliance);

- Appendix 14.2 (Waste Sites and Capacities within the Study Area); and

- Figure 14.1 (Locations of Operational Waste Management Sites Within the Study Area).

The assessment of effects on material assets and waste is aligned with and supported by relevant information and findings communicated by other environmental factors, most notably Chapter 13 (Geology, Soils, Groundwater and Land Contamination) for information on superficial mineral resources, coal workings, peat deposits, sources of contaminated land and hazardous (or special) waste; and Chapter 20 (Climate) for a unified schedule of material asset types and quantities associated with the construction of the proposed scheme. The interaction of material assets and waste with other factors has been considered in Chapter 21 (Assessment of Cumulative Effects).

Legislative and Policy Background

The assessment of material assets and waste reported in this chapter has been undertaken to satisfy the Roads (Scotland) Act 1984 (Environmental Impact Assessment) Regulations 2017 (as amended) (Scottish Government, 2017).

These regulations mandate a thorough description and assessment of both the direct and indirect significant impacts of the proposed scheme on environmental factors, including ‘material assets’ (as per Regulation 5, Section 20B (3), and Schedule 1A). Additionally, where information is available, it should include a description of any likely significant environmental effects of the proposed scheme resulting from, among other things:

- use of natural resources, considering the sustainable availability of these resources; and

- expected residues and emissions and the production, recovery and disposal of waste.

Additionally, these regulations require that the EIA should include a description of the proposed scheme, including in particular: the nature and quantity of the materials and natural resources to be used; and an estimate, by type and quantity, of waste produced during the construction and operation phases, where relevant.

The use and consumption and use of material assets and the production and disposal of waste are also subject to a complex framework of legislative and policy instruments at the national, local and applicant level. The key legislative, policy, plans and statutory guidance influencing the design, construction and assessment of the proposed scheme are identified below. This includes any emerging legislation, policies and plans, where applicable and appropriate.

National Level: Legislation

- Landfill Tax (Scotland) Act 2014 (as amended) (Scottish Government, 2014a);

- The Environmental Protection (Duty of Care) (Scotland) Regulations 2014 (as amended) (Scottish Government, 2014b);

- Waste Electrical and Electronic Equipment (WEEE) Regulations 2013 (as amended) (Scottish Government, 2013);

- The Waste (Scotland) Regulations 2012 (as amended) (Scottish Government, 2012a);

- Pollution Prevention and Control (Scotland) Regulations 2012 (as amended) (Scottish Government, 2012b);

- The Waste (Scotland) Regulations 2011 (as amended) (Scottish Government, 2011a);

- The Waste Management Licensing (Scotland) Regulations 2011 (as amended) (Scottish Government, 2011b);

- The Waste Batteries and Accumulators Regulations 2009 (as amended) (Scottish Government, 2009);

- The Landfill (Scotland) Regulations 2003 (as amended) (Scottish Government, 2003);

- The Special Waste Regulations 1996 (as amended) (Scottish Government, 1996);

- The Controlled Waste (Registration of Carriers and Seizure of Vehicles) Regulations 1991 (as amended) (Scottish Government (1991);

- The Environmental Protection Act 1990 (as amended) (Scottish Government, 1990); and

- The Control of Pollution (Amendment) Act 1989 (as amended) (Scottish Government, 1989).

Policy

- Scotland’s Circular Economy and Waste Route Map to 2030 (Scottish Government, 2024);

- Scottish Government, National Planning Framework 4 (NPF4) (Scottish Government, 2023);

- Scottish Government, Making Things Last A Circular Economy Strategy for Scotland, (Scottish Government, 2016);

- Office for Product Safety and Standards, Guidance Regulations: timber and FLEGT licences, (Office for Product Safety and Standards, 2014);

- Scottish Government, Safeguarding Scotland's Resources - Blueprint for a More Resource Efficient and Circular Economy, (Scottish Government, 2013); and

- Scottish Government, Scotland's Zero Waste Plan (Scottish Government, 2010).

Local Level:

- Perth & Kinross Council Local Development Plan 2 (LDP2), (PKC, 2019); and

- Perth & Kinross Council Supplementary Planning Guidance – Delivering Zero Waste, (PKC, 2020).

Applicant Level:

- Transport Scotland, Corporate Procurement Strategy 2024-25 (TS, 2024);

- Transport Scotland, National Transport Strategy 2 (TS, 2020);

- Transport Scotland, Road Asset Management Plan for Scottish Trunk Roads (TS, 2016a);

- Transport Scotland, A9 Dualling Programme Sustainability Strategy (TS, 2016b);

- Transport Scotland, The Strategic Environmental Design Principles (TS, 2014);

- Highways England et al, DMRB, GG 103 Introduction and general requirements for sustainable development and design (Highways England et al., 2019a); and

- Highways England et al, DMRB, LA 110 Material assets and waste (Highways England et al., 2019b); and

- Highways England et al, DMRB, LA 104 Environmental assessment and monitoring (Revision 1) (Highways England et al., 2020).

Guidance:

- Scottish Government, Duty of Care Code of Practice (Scottish Government, 2012);

- Scottish Environmental Protection Agency (SEPA), Guidance, IS IT WASTE Understanding the definition of waste (SEPA, 2006);

- SEPA Guidance, Reuse Activities and Waste Regulation (SEPA, 2017);

- SEPA et al., Technical Guidance WM3: Waste Classification (SEPA, 2021);

- SEPA Guidance, Classification of WEEE – Hazardous Substances and Persistent Organic Pollutants (POPs) (SEPA, 2022);

- SEPA Guidance, Classification of Waste Wood (SEPA, 2021);

- SEPA, Guidance, Recycled Aggregates from Inert Waste (SEPA, 2013);

- SEPA et al., Guidance on the Production of Fully Recovered Asphalt Road Planings (SEPA, 2008);

- SEPA Position Statement, Use of Incinerator Bottom Ash Aggregate in Construction, (SEPA, 2022);

- SEPA, Land Remediation and Waste Management Guidelines, (SEPA, 2009);

- SEPA, Regulatory Guidance, Promoting the Sustainable Reuse of Greenfield Soils in Construction (SEPA, 2010);

- SEPA Guidance, Recovery and Disposal of Waste in Quarries (SEPA, 2020);

- SEPA, Guidance, Management of Forestry Waste (SEPA, 2017);

- SEPA, Guidance, Developments on Peat and Off-Site Uses of Waste Peat (SEPA, 2017);

- SEPA, Use of Trees Cleared to Facilitate Development on Afforested Land (SEPA, 2014);

- SEPA, Guidance on Disposal of trees and plants infected with specific plant diseases (SEPA, 2013);

- SEPA, Technical Guidance Note, On-site management of Japanese Knotweed and associated contaminated soils (SEPA, 2008);

- SEPA, Guidance, Asbestos in Demolition Waste (SEPA,2015);

- SEPA, Technical Guidance on Activities Exempt from Waste Management Licensing, n.d;

- SEPA et al., GPP 6: Working at Construction and Demolition Sites (SEPA, 2023);

- SEPA Position Statement, Portable/Chemical Toilet Wastes (SEPA, 2019);

- SEPA, Position Statement, Crushing or Piercing of Waste Aerosol Cans for the Purposes of Recovery (SEPA, 2018);

- SEPA Guidance, Consigning Special Waste Guidance (SEPA, 2022); and

- SEPA Guidance, Prior Treatment of Waste for Landfill (SEPA, 2006).

A summary of the legislative and policy framework, and an assessment of the alignment of the proposed scheme proposals with the regulatory and policy context is provided in Appendix A14.1 (Assessment of Regulatory and Policy Compliance).

Approach and Methods

Scope and Guidance

This assessment addresses material assets and waste in accordance with DMRB LA 101 ‘Introduction to environmental assessment’ (National Highways et al., 2019) which identifies materials assets and waste as an EIA factor to be assessed.

Specifically, this assessment has been prepared in accordance with DMRB LA 110 ‘Material assets and waste’ (National Highways et al., 2019) which is the published standard for assessing and reporting the effects on material assets and waste from the delivery of motorway and all-purpose trunk road projects, and which replaced the draft unpublished HD 212/11 guidance in Scotland.

The material assets and waste assessment considers the following elements:

- the consumption of material assets. This includes materials and products from primary, secondary, recycled and renewable sources, the use of materials offering sustainability benefits, and the use of excavated and other arisings that fall within the scope of waste exemption criteria; and

- the production and disposal of waste. This includes surplus materials which can become waste during the construction of the proposed scheme, as well as other substances which the holder discards or intends or is required to discard.

Study Area

In accordance with DMRB LA 110, the assessment of material assets and waste has utilised two geographically different study areas to examine the consumption and use of primary, secondary and recycled construction materials; and the production and disposal of waste:

- The first study area is based on the construction footprint/boundary (including compounds and temporary land take) of the proposed scheme. Within these areas as shown on Figure 1.2 (Pass of Birnam to Tay Crossing Overview), construction materials will be consumed and used, and waste will be produced.

- The second study areas are based on the likely provenance of construction materials required to construct the main elements of the proposed scheme, and waste infrastructure that is likely to be suitable (permitted for waste quantity and type) to accept arisings and/or waste generated by the proposed scheme. These include:

- Angus Council, Dundee City Council, Perth & Kinross Council, Clackmannanshire Council, Falkirk Council and Stirling Council Mineral Planning Areas which are likely to be the primary source of material assets (primary, secondary and recycled aggregates) used to construct the proposed scheme. This study area has been delineated through the adoption of the Tay Area and Forth Valley Minerals Market Regions.

- Angus Council, Clackmannanshire Council, Dundee City Council, Falkirk Council, Fife Council, Perth and Kinross Council and Stirling Council Waste Planning Areas where the waste management infrastructure, likely to be used in managing the majority of waste generated by the proposed scheme, is located. This study area has been delineated through the adoption of Tayside, Central and Fife Local Authority Region.

Professional judgement (a balance of the proximity principle and value for money principle) has been applied in deriving the second study areas. This was achieved through reference to the Mineral Market Areas provided in the Collation of the Results of the 2019 Aggregate Minerals Survey for Scotland (Scottish Government, 2023) and the Tayside, Central and Fife Local Authority Region identified on Local Authority Regions Map of Scotland (Public Scotland, n.d.). The boundaries of the second study areas can be viewed through the provided hyperlinks.

It would be the appointed Contractor’s responsibility to source materials and manage waste during the construction of the proposed scheme. Typically, they would look to use local material sources and waste infrastructure, wherever practicable, to reduce the environmental impact and cost of transport and support the economic well-being of local communities. This would be managed through the measures specified in Section 14.5 (Mitigation), including but not limited to the preparation of the Contractor’s Site Waste Management Plan (SWMP).

Procurement rules mean that it is not possible for the EIA process to identify/prescribe specific material suppliers and waste management facilities to be used during construction of the proposed scheme with any certainty, and these prevent setting a precedent that would potentially tie the appointed Contractor to exclusive arrangements with specific material suppliers and waste management facilities.

Baseline Conditions

In reporting the DMRB Stage 3 Assessment, the following baseline data has been gathered from desk-based reviews of existing information, and through the analysis and review of available stakeholder information (where available):

- a description of the first study area, including information about the types and quantity of material use and waste generation associated with operation of the existing road/site;

- an assessment of the key legislative and policy instruments influencing the consideration of the consumption and use of material assets and production and disposal of waste;

- an assessment of the regional availability of construction aggregates, facilitated by a review of the Collation of the Results of the 2019 Aggregate Minerals Survey for Scotland (Scottish Government, 2023);

- a review of the locations of any mineral safeguarding sites (operational sites or sites identified within strategic planning documents for minerals extraction) and peat resources (existing or potential peat extraction sites) in relation to the proposed scheme; and

- an assessment of the current and likely future state (in the absence of the proposed scheme) of regional transfer, treatment, recycling, recovery and disposal facilities to be utilised by the proposed scheme, through a review of the Scottish Waste Sites and Capacity Data Tool (SEPA, 2024).

Although an Environmental Steering Group, comprising the members specified in Chapter 7 (Consultation and Scoping), has met regularly throughout DMRB Stages 2 and 3, there has been no specific or direct consultation at DMRB Stage 3 regarding the material assets and waste baseline with SEPA, Angus Council, Clackmannanshire Council, Dundee City Council, Falkirk Council, Fife Council, Perth and Kinross Council, or Stirling Council. This is because the necessary baseline information for the DMRB Stage 3 Assessment is readily available from the sources mentioned above.

Consultation

Information gathered via consultation has been considered in this assessment. Consultations undertaken relevant to this chapter are summarised as shown in Table 14.1 while Appendix A7.1 (Summary of Consultation Responses) provides a summary of correspondence undertaken. Further information on the consultation process is provided in Chapter 7 (Consultation and Scoping).

| Consultee | Consultation Purpose | Summary of Consultee Response |

|---|---|---|

| SEPA | To inform the early stages of the proposed scheme design and the EIA. | SEPA advised that consideration will need to be given to any waste arisings predicted from the project and it should be demonstrated how the waste hierarchy will be applied to any produced during construction and operation to limit any waste materials. |

| SEPA | Statutory consultee comments on the EIA Scoping Report | SEPA reported that it had no concerns with the proposed scope of the assessment on material assets and waste at the scoping stage. It welcomed the commitment to producing a site waste management plan (SMC-M1) and to apply the principles of the 'Waste Hierarchy' to minimise waste generation (SMC-M3), and recommended that this assessment also consider the management of any diseased trees.The Scoping Report indicated that peat is proposed to be scoped out as it is not present along the proposed scheme. Whilst SEPA had no concerns with this approach, it recommended the information supporting that conclusion be provided either before or with the EIAR. |

| SEPA | Statutory Consultee comments on the Draft DMRB Stage 3 EIAR | From a waste management perspective, it's encouraging to note the references to the waste hierarchy, Site Waste Management Plans etc throughout. |

| SEPA | Statutory Consultee comments on the Draft DMRB Stage 3 EIAR | To include reference to EASR and SEPA's Developments on Peat and Off-Site Uses of Waste Peat guidance. |

| SEPA | Statutory Consultee comments on the Draft DMRB Stage 3 EIAR | SEPA notes the residual impact of the disposal of waste produced by the project is judged to have a moderately significant impact on landfill capacity in the 'second study area' which is the Tayside, Central and Fife Local Authority Region. SEPA would encourage reuse of as much suitable material as possible within the scope of the project (providing they are legitimate/justified) to avoid the need to haul offsite. It would also encourage investigation of recovery options for surplus materials removed from site as opposed to disposal. |

While Section 14.4 (Potential Impacts and Effects) addresses the predicted waste arisings during the construction of the proposed scheme, the appointed Contractor’s SWMP will detail how the waste hierarchy has been applied to reduce the production and disposal of these wastes (as set out in Mitigation Items SMC-M1 to SMC-M4 as shown in Table 14.13). Operational waste has been excluded from this chapter for the reasons described in paragraphs 14.2.39 and 14.2.40.

Impact Assessment

This assessment focuses primarily on determining the likely significant effects of constructing the proposed scheme on the environment resulting from the consumption and use of material assets; and the production and disposal of waste.

The assessment utilises and builds on the information and data gathered as part of the DMRB Stage 2 Scheme Assessment Report (Transport Scotland, 2023) and collates additional information to quantify as accurately as possible the material assets to be consumed and used, and the wastes likely to be produced, in constructing the proposed scheme.

The material assets and waste assessment is largely a desk-based quantitative study that aims to identify the following information for the construction phase (assumed to be 2028 to 2032 for assessment purposes) and the first year of operational activities (proposed year of opening) (assumed to be 2033 for the assessment purposes).

For material assets, the assessment identifies the following:

- legislative and policy requirements;

- types and quantities of materials required to construct the project;

- information on materials that contain secondary/recycled content;

- information on any known sustainability credentials of materials to be consumed;

- the type and volume of materials that will be recovered from on or off-site sources for use on the project;

- the cut and fill balance;

- degree of minerals sterilisation; and

- details of on-site storage and stockpiling arrangements, and any supporting logistical details.

For waste, the assessment identifies the following:

- legislative and policy requirements;

- the amount of waste (by weight) that will be recovered and diverted from landfill either on site or off site (i.e. for use on other projects);

- types and quantities of waste arising from the project (site clearance, excavation and construction) requiring disposal to landfill;

- details of on-site storage and segregation arrangement for waste and any supporting logistical arrangements; and

- potential for generation of hazardous waste (type and quantity).

Significance Criteria

DMRB LA 110 sets out how effects associated with material assets and waste should be assessed through the use of a simplified assessment framework.

The descriptors of effect as shown in Table 14.2 have been used to assess the likely environmental effects of constructing the proposed scheme on material assets and waste.

Professional judgement has been used to determine which significant effect categories the proposed scheme is likely to fall within with regards to the material assets and waste elements of this factor.

|

Significance category |

Description (1) |

|

Very large |

Material assets 1) no criteria: use criteria for large categories. Waste 1) >1% reduction or alteration in national capacity of landfill, as a result of accommodating waste from a project; or 2) construction of new (permanent) waste infrastructure is required to accommodate waste from a project. |

|

Large |

Material assets 1) project achieves <70% overall material recovery/recycling (by weight) of non-hazardous Construction and Demolition Waste (CDW) to substitute use of primary materials (2); and 2) aggregates required to be imported to site comprise <1% re-used/recycled content (3); and/or (4) 3) project sterilises >1 mineral safeguarding site and/or peat resource (5). Waste 1) >1% reduction in the regional capacity of landfill as a result of accommodating waste from a project; and 2) >50% of project waste for disposal outside of the region. |

|

Moderate |

Material assets: 1) project achieves less than 70% overall material recovery/recycling (by weight) of non-hazardous CDW to substitute use of primary materials (2); and 2) aggregates required to be imported to site comprise re-used/recycled content below the relevant regional percentage target (3). Waste: 1) >1% reduction or alteration in the regional capacity of landfill as a result of accommodating waste from a project; and 2) 1-50% of project waste for disposal outside of the region. |

|

Slight |

Material assets: 1) project achieves 70-99% overall material recovery/recycling (by weight) of non-hazardous CDW to substitute use of primary materials (2); and 2) aggregates required to be imported to site comprise re-used/recycled content in line with the relevant regional percentage target (3). Waste: 1) < 1% reduction or alteration in the regional capacity of landfill; and 2) waste infrastructure has sufficient capacity to accommodate waste from a project, without compromising integrity of the receiving infrastructure (design life or capacity) within the region. |

|

Neural |

Material assets: 1) project achieves >99% overall material recovery/recycling (by weight) of non-hazardous Construction Demolition Waste (CDW) to substitute use of primary materials (2); and 2) aggregates required to be imported to site comprise >99% re-used/recycled content (3). Waste: 1) no reduction or alteration in the capacity of waste infrastructure within the region. |

(1) This table, reproduced from DMRB LA 110, uses very precise and deliberate language, specifically “OR”, “AND” and “AND/OR” after each descriptor of effect to denote which significance category should be applied. The descriptors for the material assets matter are generally summative (Large, Moderate, Slight and Neutral effects), and all descriptors need to be met in full in order to assign a relevant significance category (i.e. with the notable exception of a large effect which can be assigned when a project sterilises ≥1 mineral safeguarding site and/or peat resource). The descriptors of effect for the waste matter are either standalone (very large and neutral effects) or summative (Large, Moderate and Slight effects).

(2) In the absence of further guidance in the DMRB LA 110 standard, this descriptor has been interpreted to mean ‘project achieves XX% overall material reuse/recycling/recovery (by weight) to substitute use of primary materials on or off-site’ (i.e. within the first or second study area). Limiting this to solely ‘C&D waste’ in the context of the ‘material assets’ descriptors (where there are already separate descriptors for ‘waste’) would be impractical and inappropriate given that ‘waste’ is a legally defined term, and that the project would not look to use ‘waste’ to substitute primary materials given the potential costs, delays and risks associated with securing licenses.

(3) In the absence of a Scottish specific target in the Scotland National Application Annex to DMRB LA 110, the England Average target of 25% (provided in England National Application Annex) has been adopted for the purposes of this assessment.

(4) The published version of DMRB LA 110 includes “AND” instead of “AND/OR”. This has been changed to correct an editorial error in the original guidance that was confirmed in an email from Wilson. S (2020) at Highways England.

(5) Sterilisation is defined by DMRB LA 110 to mean ‘substantially constrain/prevent existing and potential future use and extraction of materials’. In the absence of further guidance, this has been interpreted to mean that a project would need to intersect with (sterilises) the whole of a mineral safeguarding site and/or or existing or potential peat extraction site or intersects with a significant part of a safeguarded minerals site/existing or potential peat extraction site (>50% by area). A peat resources is defined in DMRB LA 110 as ‘Existing or potential peat extraction sites’.

The potential for likely significant effects on material assets and the receiving waste management infrastructure has been determined in accordance with the criteria as shown in Table 14.3 which are aligned to the category descriptions as shown in Table 14.2.

Consequently, this framework precludes the application of a methodology to derive a measure of the significance of effect based on the receptor value and the magnitude of impact. This is consistent with DMRB LA 104 ‘Environmental assessment and monitoring’ (National Highways et al., 2020) which states that ‘where relevant, individual environmental factors can set out variations in value, magnitude and significance description requirements’.

|

Significance category |

Description |

|

Significant (one or more criteria met) |

Material assets: 1) category description met for Moderate or Large effect. Waste: 1) category description met for Moderate, Large or Very Large effect. |

|

Not significant |

Material assets: 1) category description met for Neutral or Slight effect. Waste: 1) category description met for Neutral or Slight effect. |

Assessment Methodology

DMRB LA 104 requires that the significance of an effect shall be reported including embedded mitigation measures.

A number of embedded mitigation measures have been included as part of the proposed scheme design to reduce certain environmental effects. These include:

- careful designing of the proposed scheme to reduce the consumption and use of material assets, the production and disposal of waste, and avoid key receptors where practicable; and

- compliance with those regulatory and legislative regimes as required by law that apply irrespective of the EIA process, including the consents and licenses identified in Section 14.1 (Introduction).

DMRB LA 104 specifies that residual effects shall be reported after the assessment of the effectiveness of essential mitigation measures identified in Section 14.4 (Potential Impacts and Effects) which are required to avoid, reduce and, if possible, offset likely significant adverse environmental effects.

Assigning significance of an effect, taking account of embedded mitigation, and again after an assessment of the effectiveness of essential mitigation demonstrates the positive contribution of all committed mitigation.

Cumulative Effects

Potentially significant cumulative effects of the proposed scheme, and those of the proposed scheme in combination with other reasonably foreseeable developments, are assessed in Chapter 21 (Assessment of Cumulative Effects).

Limitations of the Assessment

The assessment on material assets and waste receptors presented in this chapter currently has limitations, as it is predominantly based on a review of the baseline information and DMRB Stage 3 preliminary design information available at the DMRB Stage 3 Design Fix (April 2025).

Whilst the baseline data sources used in this assessment represent the most recently available stakeholder information, there is a general lag (in years) of materials, waste processing and landfill capacity data in the UK/Scotland and conditions may have changed since publication of this data (e.g. as mineral planning permissions are granted and as existing reserves are worked; and as waste management licenses/permits are granted, modified and surrendered, and available capacity is utilised).

Although checks are made by stakeholders for anomalies or errors in their data prior to publication, it cannot be guaranteed that these data sets are error free, or whether any commercial decisions have been taken by site operators that may have affected these data. It is recognised that some mineral and landfill operators do not release information for reasons of commercial confidentiality. The resulting data gaps may reduce the value of the data that is made publicly available.

The availability of material assets and waste management capacity may also be impacted by other buildings and infrastructure projects taking place at the time of construction of the proposed scheme as detailed in Chapter 21 (Assessment of Cumulative Effects). Furthermore, changes to the permitted minerals and waste management capacity of waste facilities during the construction of the proposed scheme cannot be predicted with any precision. Notwithstanding, policy, strategic and legislative drivers are likely to facilitate that sufficient capacity continues to be provided.

Whilst the DMRB Stage 3 preliminary design information provides an initial estimate of the key materials likely to be required during the construction of the proposed scheme, it does not quantify all material and product types that would be required. Therefore, the estimated quantities presented in this assessment can only be taken as approximate and indicative. The assessment parameters, which form the basis of the material assets and waste forecasting, will inevitably be subject to some changes as the proposed scheme evolves through the detailed design and construction stages.

Given that the estimated material assets required, and waste generated, may change between this assessment and eventual construction, a 15% uplift has been applied to all material and waste quantities. This figure is derived from the default contingency factor for early design as outlined in the RICS Professional Standard - Whole Life Carbon Assessment for the Built Environment (Royal Institution of Chartered Surveyors, 2024). This uplift is intended to account for additional materials not included in the current estimate and potential changes between the specimen design and construction.

Furthermore, there is also limited precise information currently available as described in the subsequent paragraphs.

For material assets:

- the types and quantities of materials used during the operation of the existing road/site;

- precise provenance of imported materials and products;

- information on materials that contain secondary/recycled content;

- information on any known sustainability credentials of materials to be consumed;

- the type and volume of materials that will be recovered from on or off-site sources for use on the project; and

- details of on-site storage and stockpiling arrangements, and any supporting logistical details.

For waste management:

- the types and quantities of waste produced associated with operation of the existing road/site;

- the amount of waste (by weight) that will be recovered and diverted from landfill either on site or off site (i.e. for use on other projects);

- types and quantities of waste arising from the project (demolition, excavation arisings and remediation) requiring disposal to landfill;

- details of on-site storage and segregation arrangement for waste and any supporting logistical arrangements; and

- the chosen waste management methods (recycling, recovery, disposal) and precise geographical locations for managing each waste stream that cannot be re-used on-site.

The above limitations are not untypical of this stage in the design lifecycle, and the information presented in this chapter is considered of an appropriate level of detail to undertake a proportionate assessment in line with DMRB LA 110. Therefore, the assessment has been supported by the following additional information, which has been used to populate these data gaps and allow the assessment of the material assets and waste factor to be undertaken on a precautionary basis:

- Waste and Resources Action Programme (WRAP) guidance – for indicative recycled content of standard construction materials and products;

- Royal Institution of Chartered Surveyors (RICS) guidance – for wastage rates and typical end-of-life pathway percentages for common construction materials and products; and

- Professional judgment.

Material assets and waste can affect the full range of environmental media and assessment factors. It is acknowledged that, depending on how material assets and waste are managed, indirect adverse effects may arise (from greenhouse gas emissions; water consumption; visual effects, dust, noise, vibration, vehicle emissions, traffic and other potential causes of nuisance; and water pollution amongst others).

Such effects do not form part of the material assets and waste assessment and are considered as part of the other technical chapters in this EIAR where relevant. This chapter should therefore be read in conjunction with Chapters 16, 17 and 18 (Population and Human Health); Chapter 13 (Geology, Soils, Groundwater and Land Contamination); Chapter 19 (Road Drainage and the Water Environment); Chapter 8 (Air Quality); Chapter 15 (Noise and Vibration); and Chapter 20 (Climate).

The impacts from the consumption of material assets and the production and disposal of waste are largely dispersed, rather than affecting specific receptor locations. It is, therefore, not possible to assess, either qualitatively or quantitatively, the indirect environmental effects from either upstream materials extraction and production facilities, or downstream waste management and disposal facilities within the expansive study area. The exception to this is the indirect carbon emissions that fall within the scope of Chapter 20 (Climate).

As reported in the DMRB Stage 3 Scoping Report (Transport Scotland, 2024), operational effects associated with material assets and waste have not been assessed, as they were considered to be not significant (by quantity) in the context of the proposed scheme. Furthermore, DMRB LA 110 specifies that the environmental assessment shall only report on the first year of operational activities (i.e. proposed year of opening).

It has been assumed that no significant maintenance activities would occur during the proposed year of opening, and therefore no significant materials consumption or waste generation is likely to be realised. Whilst it is appreciated that the first year of operational activities is a time period not necessarily confined to operational effects, any construction phase effects overlapping within this period are captured within the construction phase assessment.

Notwithstanding this, the design process would inherently seek to reduce the consumption and use of material assets; and the production and disposal of waste throughout the lifecycle of the proposed scheme. Design choices and the choice of materials will make a significant contribution to reducing the environmental effects, associated with material assets and waste during operation, by influencing the required method and frequency of maintenance, and facilitating opportunities to recover and regenerate materials and products at the end of first life to support a circular economy.

It is also assumed that the assessment of any environmental effects associated with material assets and waste during any large scale future maintenance, renewal, or improvement works beyond the proposed year of opening, would be undertaken by the Road Operating Company in accordance with the requirements of the Overseeing Organisation.

Baseline Conditions

A desk-based assessment has been undertaken in order to establish, for the first and second study areas, the existing and likely future conditions (in the absence of the proposed scheme) for material assets and waste.

Baseline data has been collected at national, regional and sub-regional levels, including:

- availability of construction aggregates;

- presence of mineral safeguarding sites and/or peat resources;

- construction, demolition and excavation waste arisings; and

- information on regional waste transfer, treatment, recycling, and disposal facilities capacity.

Material Assets

For the purpose of this assessment, material assets are considered to be the physical resources in the environment, which may be of human or natural origin.

Primary aggregates have been chosen to act as a proxy indicator of material assets given that large quantities of aggregates are typically required for motorway and all-purpose trunk road projects, e.g. for direct use in unbound bulk fill, capping, sub-base, filter drains, and for indirect use in bound applications such as concrete and asphalt.

This was also considered appropriate due to the prominence given to aggregates in DMRB LA 110, and the fact that aggregates are likely to constitute the key construction material (by weight) to be consumed and used in the construction of the proposed scheme.

Existing Aggregates Consumption

The operational maintenance of the existing A9 consumes both unbound aggregates (used as sub-base and drainage applications) and bound aggregates (used in ready mixed concrete, asphalt and pre-cast concrete products).

There are no precise figures available regarding the baseline quantities of operational/ maintenance aggregates consumption across the first study area. Based on recent experience on other road schemes, this information is unlikely to be available at sufficient granularity to be useful in reporting the baseline conditions associated with the first study area.

Notwithstanding this, operational effects have been scoped out of the assessment for the reasons described in paragraphs 14.2.39 and 14.2.40.

Primary Aggregate Reserves

The principal materials used in road construction are primary aggregates, including sand, gravel and crushed rock. Primary aggregates are produced from naturally occurring mineral deposits and used for the first time, as defined by the in its Mineral Planning Factsheet: Construction Aggregates (British Geological Survey (BGS), 2019)).

Aggregates are normally defined as being hard, granular materials which are suitable for use on their own or with the addition of cement, lime or bituminous binders. However, a proportion of aggregates sales are for construction fill or other uses where soft and non-granular material may be acceptable or specified.

Crushed rock typically has a much wider range of uses than sand and gravel, including as a source of both coarse and fine concrete aggregate, other screened and graded aggregates and for other construction uses, including fill. However, its main use is in road construction, both unbound, primarily for the foundations of roads, and bound with either bitumen or cement in the upper layers.

Scotland’s National Planning Framework 4 (NPF4) continues the UK landbank approach to planning for the supply of construction aggregates. Adopted in February 2023, NPF4 details the long-term planning strategy for Scotland to 2045. In terms of minerals, NPF4 sets out planning policies which ensure that a steady supply of construction aggregates is maintained to meet the needs of society and the economy in an acceptable and sustainable manner.

NPF4 requires those preparing local development plans to adopt a landbank approach to planning for the supply of construction aggregates. This approach is intended to ensure that a stock of reserves, with planning permission, is maintained to ensure adequate supplies of aggregates. Those preparing local development plans are required through NPF4 to maintain a landbank of permitted reserves equivalent to a minimum of 10 years supply at all times. The ten-year period recognises the likely time that it takes to bring a new site into full production.

The Collation of the results of the 2019 Aggregate Minerals Survey for Scotland (Scottish Government, 2023) confirms that the second study area (Tay Area and Forth Valley) had a total landbank for crushed rock and sand and gravel of 30 years and 9 years respectively at the end of 2019 (the most recent year available):

- Crushed rock: 30 years for crushed rock from maximum supply at 2019 sales levels. In 2019, total sales of crushed rock equated to 434,000 tonnes.

- Sand and gravel: 9 years for crushed rock from maximum supply at 2019 sales levels. In 2019, total sales of sand and gravel equated to 441,000 tonnes.

Review of the British Geological Survey Directory of Mines and Quarries (BGS, 2020) suggests that the mines and quarries in the study area are able to supply a wide range of materials, including but not limited to primary aggregate, concrete and asphalt products. It can reasonably be inferred that there is likely to be an adequate supply of construction aggregates available within the study area to construct the proposed scheme; and policy, strategic and legislative drivers are likely to facilitate that sufficient capacity is provided.

The appointed Contractor would source materials for the construction of the proposed scheme, and typically they would look to use local suppliers and to re-use materials on-site to reduce the environmental impact and cost of waste transport and to support the economic well-being of the local communities in line with the proximity principle. Procurement rules mean that it is not possible to prescribe specific materials sources to specific quarries, manufacturers or suppliers.

Both secondary and recycled aggregates can be used, subject to the Specification for Highway Works (Department for Transport (DfT), 2022), as alternatives to primary aggregate and have a number of benefits, including the reuse of secondary and waste materials and reducing the impact of primary extraction:

- Secondary aggregates are typically by-products of industrial processes. These can be sub-divided into manufactured and natural aggregates, depending on their source and can include materials such as pulverised fuel ash, ground granulated blast furnace slag, incinerator bottom ash and recycled glass.

- Recycled aggregates are typically derived from reprocessing materials previously used in construction, e.g. road planings or crushed concrete from construction and demolition (C&D) activities.

Zero Waste Scotland has previously produced an Aggregate Quality Protocol Suppliers Directory (Zero Waste Scotland, 2024) of suppliers of recycled aggregates who have successfully demonstrated their compliance with the Quality protocol: aggregates from inert waste - End of waste criteria for the production of aggregates from inert waste (WRAP, 2013). The details on the locations of suppliers, identified from the directory, that are within the second study area and could be utilised for the proposed scheme, are as shown in Table 14.4.

These suppliers could be utilised to provide recycled aggregates or potentially to process waste from the proposed scheme. Other potential sources of alternative aggregates would be investigated as the detailed design is progressed, including opportunities to re-use site-won materials and materials from major development sites in the area. The second study area, for material assets, has been expanded to include the Fife Council area given that these sites can be viewed as both material suppliers and waste recovery facilities.

| Sub-region | Address of Recycled Aggregate Supplier | Products |

|---|---|---|

| Angus | Walkkmill - Geddes Group, Waulkmill Quarry, DD11 4UT | Sub-base (Type 1) and capping (6F5). |

| Dundee | Ardownie - Geddes Group, Ardownie Quarry, DD5 4HW | Sub-base (Type 1) and capping (6F5). |

| Perth & Kinross | Collace Quarry - Tayside Contracts, PH2 6JB | General fill; sub-base (Type 1); sub-base (Type 4); and drainage and filter bedding. |

| Fife | Clatchard Quarry - Breedon Aggregates Scotland Ltd, KY14 6JJ | General fill |

| Fife | Langside Quarry - Purvis Group, KY8 5SG | General fill and Sub-base (Type 1) |

| Fife | Bowhill Recycling Centre - Purvis Group, KY5 0ND | General fill; sub-base (Type 1); and capping (6F5) |

| Fife | Birchwood Sidings - Belliston Quarry Co Ltd, KY9 1JS | General fill; sub-base (Type 1); and capping (6F5) |

| Fife | Achilty Quarry - Leiths Scotland Ltd, KY2 5XD | Sub-base (Type 1); capping (6F3); and asphalt planings |

| Fife | Grant House - Grant Construction Services Ltd, KY11 9YX | Capping (6F5) |

| Falkirk | Eagle Recycling - Purvis Group | Sub-base (Type 1); capping (6F5); and recycled sand (0/6mm) |

Minerals Safeguarding Sites

Scotland’s National Planning Framework 4 requires that: ‘Local development plans should safeguard important workable mineral resources, which are of economic or conservation value, and take steps to ensure these are not sterilised by other types of development’.

A review of the Perth & Kinross Local Development Plan 2 (Perth & Kinross Council, 2019) has not identified any mineral safeguarding sites (i.e. operational extraction sites or mineral sites specifically identified/allocated in strategic planning documents as those that will be mined or extracted) within or in close proximity to the first study area. Superficial deposits, where present, are recorded as alluvium, river terrace deposits, glaciofluvial deposits and Devensian glacial till.

The majority of the existing A9 is underlain by glaciofluvial deposits comprising sand and gravel with local lenses of silt, clay and organic matter. Where the existing A9 is located close to the River Tay, for example at Inver, the River Tay Crossing and west of Little Dunkeld, the underlying superficial material comprises river alluvium, a silty clay which can contain layers of silt, sand, gravel and peat.

River terrace deposits are recorded in the west of the study area, further up slope on the edge of the floodplain, and are generally described as being comprised of sand and gravel with local lenses of silt, clay or peat. Glacial till is generally recorded on the higher ground of the valley sides and is typically composed of a wide range of poorly sorted clays, sands and gravels.

Peat Resources

No peat resources (i.e. existing or potential peat extraction sites) have been identified within the first study area. For the purposes of this assessment, this equates to sites with an extant planning permission for commercial peat extraction.

No peat deposits are recorded on Minerals Information Online (BGS, 2025) within 250m of the first study area. In addition, the entire study area is classified as Class 0 (mineral soils where peatland habitats are not typically found) by the Carbon and Peatland map 2016 (Nature Scotland, 2016) with a small area at Birnam, Little Dunkeld and Dunkeld classified as Class -2 (non-soil; i.e. loch, built up area, rock and scree).

Notwithstanding this, a review of ground investigation data indicated that peat/peaty soils have been encountered locally in a relatively small number of exploratory hole locations. Additional details on peat as a soil resource, rather than a mineral resource, can be found in Chapter 13 (Geology, Soils, Groundwater and Land Contamination).

Waste Production and Disposal

Existing Waste Production

Waste produced during the operational maintenance of the existing A9 is likely to include asphalt planings, soft estate vegetative arisings, road sweepings, gully arisings, oil separator waste, animal by-products (roadkill) and litter.

There are no precise figures available regarding the baseline quantities of operational/ maintenance waste generation across the first study area. Based on recent experience on other road schemes, this information is unlikely to be available at sufficient granularity to be useful in reporting the baseline conditions associated with the first study area.

Notwithstanding this, operational effects have been scoped out of the assessment for the reasons described in paragraphs 14.2.39 and 14.2.40.

Construction and Demolition Waste Generation

The construction of the proposed scheme will produce a range of waste types including inert, non-hazardous and hazardous (or special) wastes. The majority of wastes are assumed to be inert and non-hazardous C&D wastes.

However, there will also be Municipal Solid Waste (MSW) generated by construction workers (e.g. canteen, office and staff welfare waste), and smaller quantities of hazardous waste (e.g. contaminated soils, paints and solvents, admixtures, spill absorbent materials, waste lubricants, waste electrical and electronic equipment, and batteries).

Scotland’s Environment Waste Discover Data Tool (SEPA, 2024) provides a break-down of all waste types for 2011 to 2022, and the trend for Scottish waste landfilled since 2005. This tool records that Scotland generated approximately 4,616,588 tonnes of C&D waste in 2022 (the latest year available), the composition of which is as shown in Table 14.5. No further regional breakdown is provided.

The Waste Discover Data Tool also confirmed that 90.4% of inert and non-hazardous C&D waste was recorded as having been recycled in 2022 (88.8% average between 2011 and 2022), against the EU Waste Framework Directive 2008/98/EC target of 70% by 2020. C&D recycling rates are from data provided to Europe for reporting under the Waste Framework Directive. C&D recycling excludes hazardous waste and naturally occurring soil and stones coded under 17 05 04 of the European Catalogue List of Wastes.

| Waste type | Generated in 2022 (t) | Composition in 2022 (%) |

|---|---|---|

| Dredging spoils | 5,129 | 0.11% |

| Glass wastes | 20,277 | 0.44% |

| Household and similar wastes | 2,610 | 0.06% |

| Metallic wastes, ferrous | 85,316 | 1.85% |

| Metallic wastes, mixed ferrous and non-ferrous | 20,415 | 0.44% |

| Metallic wastes, non-ferrous | 10,329 | 0.22% |

| Mineral waste from construction and demolition (1) | 1,359,714 | 29.45% |

| Other mineral wastes | 2,215 | 0.05% |

| Plastic wastes | 7,825 | 0.17% |

| Soils | 2,981,523 | 64.58% |

| Vegetal wastes | 792 | 0.02% |

| Wood wastes | 120,443 | 2.61% |

| Total | 4,616,588 | 100% |

(1) Includes concrete, bricks and gypsum waste; bituminous and tar bound road-surfacing waste; and certain mixed C&D streams.

The summary document and commentary text to the Waste Discover Data Tool confirms that annual C&D waste generation varies considerably depending on construction activities and major projects in Scotland, with year-on-year changes in C&D waste ranging from -27% to +26%. The generation of C&D waste is therefore sensitive to large regional projects, which accounts for the large annual variation in C&D waste generated.

Current Waste Treatment, Recycling and Recovery Baseline

The available waste treatment, recycling, recovery and disposal infrastructure within the second study area accepting inert, non-hazardous and hazardous commercial and industrial waste (including C&D waste) is summarised as shown in Table 14.6. This is provided for the 2023 calendar year (the most recent year available), and is based on a review of Scotland’s Waste Sites and Capacities Data Tool (SEPA, 2024).

A number of the waste facilities, as shown in Table 14.6, operate more than one waste management activity on-site and includes both merchant and restricted facilities. The reported tonnages therefore represent the total wastes inputted to each facility type and not tonnages per activity. Similarly, the reported capacities are for the facility type as a whole, not per activity as these data are not currently published by SEPA.

| Waste Management Facility Type | Annual Waste Capacity (t) | Waste Inputs (2023) (t) | Utilised Capacity |

|---|---|---|---|

| (2023) (t) | |||

| Civic amenity | 181,854 | 69232 | 38% |

| Civic amenity/Composting | 91,000 | 14,894 | 16% |

| Civic amenity/Transfer station | 253,053 | 101,489 | 40% |

| Civic amenity/Transfer station/ Landfill (not operational) | 7,000 | 5,234 | 75% |

| Co-incineration | 685,000 | 410,988 | 60% |

| Composting/Anaerobic digestion | 97,620 | 46,937 | 48% |

| Composting/Landfill (not operational) | 37,000 | 17,448 | 47% |

| Incineration | 424,000 | 210,942 | 50% |

| Landfill | 849,398 | 58,237 | 7% |

| Landfill/Civic amenity/ Composting/Anaerobic digestion/Other treatment | 436,500 | 189,405 | 43% |

| Landfill/Civic amenity/ Composting/Other treatment | 302,500 | 144,738 | 48% |

| Landfill/Composting | 165,000 | 29,256 | 18% |

| Landfill/Other treatment | 898,500 | 320,540 | 36% |

| Metal recycler | 537,255 | 239,029 | 44% |

| Metal recycler/Transfer station | 179,749 | 72,813 | 41% |

| Other treatment | 130280 | 330088 | 253% |

| Transfer station | 2,794,269 | 808,567 | 29% |

| Transfer station/Anaerobic digestion | 90,000 | 18,836 | 21% |

| Transfer station/Composting | 304,999 | 134,490 | 44% |

| Transfer station/Landfill (not operational) | 2,499 | 248 | 10% |

| Transfer station/Other treatment | 645,850 | 208676 | 32% |

| Total capacity/inputs, and average utilised capacity (2023) | 9,113,326 | 3,432,087 | 48% |

Reference to the Waste Sites and Capacities Data Tool identifies that there was a total of 148 operational waste sites in the second study area (21 in Angus Council area, 16 in Dundee City Council area, 27 in the Perth & Kinross Council area, 6 in Stirling Council area, 27 in Falkirk Council area, 5 in Clackmannanshire Council area and 46 in Fife Council area) at the end of 2023. It can therefore be assumed on the basis of the above facility types, throughputs and capacities, that there will be significant opportunity for appropriate wastes arising during the construction of the proposed scheme to be reused, recycled or otherwise recovered via appropriate means, subject to the waste hierarchy of prevent, prepare for reuse, recycle, recover and dispose as shown in Diagram 14.1.

A more detailed summary of the available waste management infrastructure in the second study area is provided in Appendix A14.2 (Waste Sites and Capacities within the Study Area), including the type, locations and capacities of each facility. The locations of the operational waste management infrastructure within the second study area are mapped as shown on Figure 14.1, which includes both merchant and restricted waste management facilities.

Current Landfill Capacity Baseline

For wastes which cannot be reused, recycled or otherwise recovered, disposal to landfill would be required. Scotland’s Waste Sites and Capacities Data Tool details total remaining inert and non-hazardous landfill capacity in the second study area at the end of 2023, and this is as shown in Table 14.7.

The baseline review suggests that there is currently available inert landfill capacity within the second study area for the majority of wastes likely to arise from the construction of the proposed scheme, but there is limited non-hazardous and hazardous landfill capacity.

Table 14.7: Permitted and Remaining Capacity of Operational Landfills (Inert and Non-Hazardous) in the Second Study Area, 2023 (SEPA, 2024)

| Site Name | Council Area | Approx Distance | Annual capacity on permit 2023 (t) | Total capacity on permit 2023 (t) | Remaining Capacity at the end of 2023 | Landfilling End Date |

|---|---|---|---|---|---|---|

| Border Quarry Landfill | Angus | ~70km | 24,999 | N/A | 341,013 | 01/12/2050 |

| Ardownie Landfill | Angus | ~60 m | 75,000 | N/A | 263,320 | 01/12/2035 |

| Prettycur Landfill | Angus | ~50km | 24,999 | 53,067 | 5,218 | 01/12/2024 |

| Hatton Mill Landfill | Angus | ~70km | 75,000 | 1,875,270 | 1,818,385 | 01/12/2034 |

| Site Name | Council Area | Approx Distance | Annual capacity on permit 2023 (t) | Total capacity on permit 2023 (t) | Remaining Capacity at the end of 2023 | Landfilling End Date |

|---|---|---|---|---|---|---|

| Border Quarry Landfill | Angus | ~70km | 24,999 | N/A | 341,013 | 01/12/2050 |

| Ardownie Landfill | Angus | ~60 m | 75,000 | N/A | 263,320 | 01/12/2035 |

| Hatton Mill Landfill | Angus | ~70km | 75,000 | 1,875,270 | 1,818,385 | 01/12/2034 |

| West Carron Landfill | Falkirk | ~90km | 77,400 | 5,000,000 | 218,332 | 01/12/2027 |

| Avondale Landfill | Falkirk | ~100km | 720,000 | 8,350,000 | 376,000 | 01/11/2025 |

| Lochhead Landfill | Fife | ~70km | 382,500 | 7,946,400 | 96,217 | 01/12/2025 |

| Lower Melville Woods Landfill | Fife | ~60km | 282,500 | 2,701,000 | 61,830 | 01/12/2025 |

| Site Name | Council Area | Approx Distance | Annual capacity on permit 2023 (t) | Total capacity on permit 2023 (t) | Remaining Capacity at the end of 2023 | Landfilling End Date |

|---|---|---|---|---|---|---|

| Avondale Quarry | Falkirk | ~100km | 200,000 | 800,000 | 31,000 | 01/12/2025 |

| Site Name | Council Area | Approx Distance | Annual capacity on permit 2023 (t) | Total capacity on permit 2023 (t) | Remaining Capacity at the end of 2023 | Landfilling End Date |

|---|---|---|---|---|---|---|

| Total (Mt) | N/A | N/A | 1.86 | 26.73 | 3.21 | N/A |

(1) These non-hazardous landfills also accept stable non-reactive hazardous waste in separate dedicated landfill cells (e.g. asbestos). All existing operational non-hazardous landfills in the second study area are currently scheduled to have ceased infilling by the start of construction in 2028. The closest operational non-hazardous landfills with sufficient likely remaining capacity beyond 2028 are: Greengairs Landfill, Meikle, Drumgray Road, Airdrie, ML6 7TD with 3,579,070 t of remaining capacity at the end of 2023 and an estimated date for ceasing landfill of 01/03/2038 (~100km); Easter Hatton Farm, Balmedie, Aberdeenshire, AB23 8YY with 1,593,000 t of remaining capacity at the end of 2023 and an estimated date for ceasing landfill of 01/12/2056 (~150km).

(2) Reference to SEPA’s Consultation Hub (SEPA, 2022) confirms that SEPA received an application from Avondale Environmental Limited in 2021 for a new Pollution Prevention and Control Permit (PPC) (PPC/A/SEPA2021-7010) to undertake landfill activities in a new hazardous landfill cell at their waste management complex. This new application looks to increase the hazardous waste landfill operations within the wider Avondale Environmental waste management complex by utilising previously undeveloped land to construct a new cell area. The design will provide an extra 220,000 m3 (or 352,000 t) of void space for the landfill of hazardous waste. Whilst SEPA has assessed the application and has drafted new permit conditions along with a draft decision document, which recommended that a permit variation be issued, its Consultation Hub would suggest that the application was withdrawn by the applicant on the 15/08/2024. Currently, there is no specific timeline for future applications by Avondale Environmental Limited for additional capacity at Avondale Quarry Landfill.

Future Waste Treatment, Recycling and Recovery Baseline

Waste treatment, recycling and recovery facilities are typically characterised by large annual throughput capacities; consequently, large step changes in capacity (as single facilities are commissioned) have an exaggerated impact on the historical trend. Waste treatment, recycling and recovery capacity cannot therefore be realistically projected forward to the construction phase.

The waste treatment and recovery infrastructure capacity will therefore be based on the most recent available Waste Sites and Capacities Data Tool capacity/input data that suggests that there is likely to be adequate opportunity for appropriate wastes arising during the construction of the proposed scheme to be recycled or subject to other recovery, subject to the waste hierarchy.

Waste transfer, treatment, recycling and recovery infrastructure facilities are considered to be a beneficiary of incoming materials by driving the management of arisings up the waste hierarchy, and by facilitating a circular approach to the management of materials. Whilst such facilities are a factor in the reduction in the significance of effect associated with waste disposal, they are not considered to be a sensitive receptor for the purposes of assessment in the same way as landfills, which are a finite resource.

Professional experience has shown that waste markets are flexible and adapt to changing markets within a region. It is expected that whilst the actual waste facilities available may change over the course of construction, the overall capacity is likely to remain similar as the market responds.

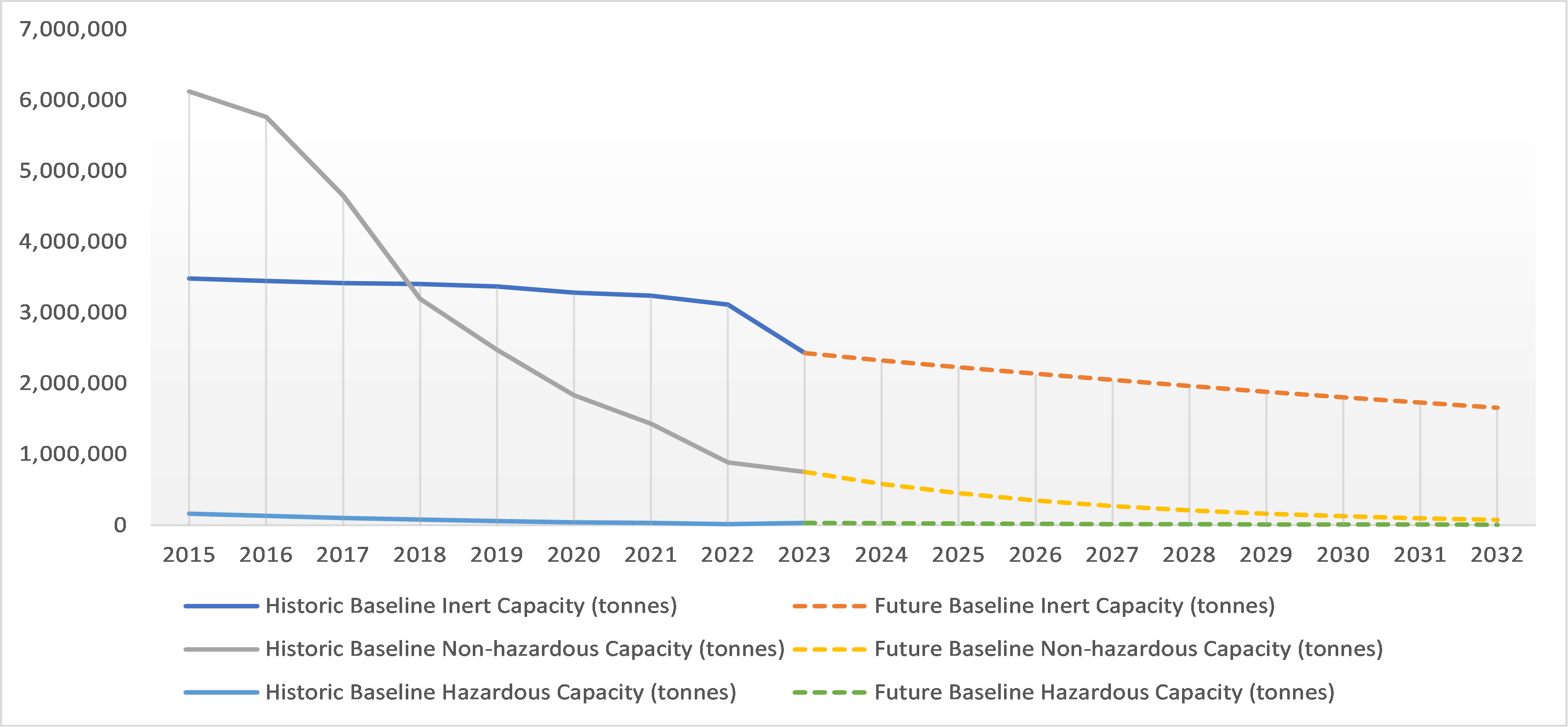

Future Forecast Landfill Capacity

Projected future landfill capacity values have been estimated and are illustrated as shown in Table 14.8 and Diagram 14.2 respectively, based on the average annual percentage change in remaining inert and non-hazardous landfill capacity for the years for which consistent data are available in Waste Sites and Capacities Data Tool (i.e. 2015 to 2023):

- inert landfill (-4.14%);

- non-hazardous landfill (-22.50%); and

- hazardous landfill (-13.37%).

The predicted changes in landfill capacity are derived from the historic time-based data provided in the Waste Sites and Capacities Data Tool (i.e. remaining landfill capacity at the end of each calendar year). These data have been projected forward to 2032, using the calculated average annual capacity change in landfill capacity from 2015 to 2023, in order to provide an estimate of the remaining landfill capacity that may be available during the construction of the proposed scheme (assumed to be between 2028 and 2032 for assessment purposes).

The estimates, as shown in Table 14.8 and Diagram 14.2, assume continuation of a similar trend, in the subtraction and addition of landfill capacity, as that reported by Waste Sites and Capacities Data Tool between 2015 and 2023.

| Timeline | Inert capacity - Historic baseline | Inert capacity - Future | ||||

|---|---|---|---|---|---|---|

| baseline | Non-hazardous - Historic baseline | Non-hazardous - Future baseline | Hazardous capacity -Historic baseline | Hazardous capacity - Future baseline | ||

| 2015 | 3,483,145 | N/A | 6,124,181 | N/A | 164,264 | N/A |

| 2016 | 3,450,026 | N/A | 5,761,346 | N/A | 133,601 | N/A |

| 2017 | 3,415,908 | N/A | 4,652,778 | N/A | 100,000 | N/A |

| 2018 | 3,405,720 | N/A | 3,198,700 | N/A | 80,000 | N/A |

| 2019 | 3,368,112 | N/A | 2,477,702 | N/A | 59,180 | N/A |

| 2020 | 3,281,932 | N/A | 1,836,508 | N/A | 43,557 | N/A |

| 2021 | 3,239,328 | N/A | 1,434,590 | N/A | 34,732 | N/A |

| 2022 | 3,114,578 | N/A | 885,694 | N/A | 17,225 | N/A |

| 2023 | 2,427,936 | N/A | 752,379 | N/A | 31,000 | N/A |

| 2024 | N/A | 2,327,491 | N/A | 583,061 | N/A | 26,856 |

| 2025 | N/A | 2,231,202 | N/A | 451,846 | N/A | 23,266 |

| 2026 | N/A | 2,138,897 | N/A | 350,161 | N/A | 20,156 |

| 2027 | N/A | 2,050,410 | N/A | 271,359 | N/A | 17,462 |

| 2028 | N/A | 1,965,584 | N/A | 210,291 | N/A | 15,128 |

| 2029 | N/A | 1,884,267 | N/A | 162,967 | N/A | 13,106 |

| 2030 | N/A | 1,806,314 | N/A | 126,292 | N/A | 11,354 |

| 2031 | N/A | 1,731,586 | N/A | 97,871 | N/A | 9,836 |

| 2032 | N/A | 1,659,950 | N/A | 75,845 | N/A | 8,521 |

| Average annual capacity 2028-32 (tpa) | N/A | 1,809,540 | N/A | 134,653 | N/A | 11,589 |

Although there is generally a reducing trend for landfill disposal in Scotland, the forecast future baseline landfill capacity suggests that there is likely to be adequate inert landfill capacity (~1,809,540 tpa); limited non-hazardous landfill capacity (134,653 tpa) and very limited hazardous landfill capacity (11,589 tpa) available in the second study area between 2028 and 2032 to support the construction of the proposed scheme.

Notwithstanding this, it is envisaged that the vast majority of the inert and non-hazardous waste arising from constructing the proposed scheme will be re-used, recycled or otherwise recovered within the first or second study area in accordance with the legislative and policy regime. This assumption is validated by the available Scottish statistics with 90.4% of inert and non-hazardous C&D waste having been recycled and diverted from landfill in 2022 (the most recent year available).

This will be required in order to demonstrate the proposed scheme’s contribution to achieving Scotland’s Zero Waste Plan target of recycling 70% of all waste, and landfilling a maximum of 5% by 2025; and to comply with the provisions of The Waste (Scotland) Regulations 2011 (e.g. taking all such reasonable measures available to apply the waste hierarchy) and The Waste (Scotland) Regulations 2012 (e.g. banning the landfilling of segregated waste).

Any landfills that have ceased infilling at the time of construction, and are no longer accepting waste, may also still require inert and non-hazardous materials for capping and restoration purposes, and therefore may be amenable to accepting any suitable surplus materials arising from construction subject to waste regulatory controls (e.g. waste management licensing, pollution prevention and control permitting or exemptions).

Sensitivity of the Identified Resources and Receptors

The baseline environment is comprised of receptors which have been defined geographically based on the likely environmental effects, associated with the use and consumption of material assets and the production and disposal of waste, as set out in DMRB LA 110. Whilst these receptors and an indication of their sensitivity have been summarised as shown in Table 14.9, it should be noted that the DMRB LA 110 simplified significance framework precludes the need to assign a sensitivity rating to the identified receptors for the purposes of assessment.

| Receptor | Sensitivity of the Receptor |

|---|---|

| Primary, secondary and recycled aggregate resources | There is likely to be a good supply of both primary and recycled aggregates within the study area to construct the proposed scheme. Although, there is currently limited information on the availability of secondary aggregates. |

| Mineral safeguarding sites and peat resources | There are no mineral safeguarding sites or peat resources within or in close proximity to the first study area. Given the absence of any mineral safeguarding sites and peat resources within the first study area, these receptors have been scoped out of any further assessment of potential impact and effects in this chapter. |

| Waste management infrastructure | There is likely to be sufficient inert landfill capacity (~1,809,540 tpa) within the second study area to support the construction of the proposed scheme. However, there is anticipated to be limited non-hazardous landfill capacity (134,653 tpa) and very limited hazardous landfill capacity (11,589 tpa). However, it should also be noted that all non-hazardous and hazardous landfills in the second study area are currently scheduled to have ceased infilling by the start of construction in 2028 (as shown in Table 14.7). |

In addition to the generalised receptors as shown in Table 14.9 for material assets and waste, additional receptors and designated areas are identified in Chapters 16, 17 and 18 (Population and Human Health); Chapter 13 (Geology, Soils, Groundwater and Land Contamination); Chapter 19 (Road Drainage and the Water Environment); Chapter 8 (Air Quality); Chapter 15 (Noise and Vibration); and Chapter 20 (Climate). Designated sites located within 500m of the proposed scheme extents are as shown on Figure 1.2 (Key Environmental Constraints).

The proposed scheme design was developed to be cognisant of the identified constraints including, but not limited to topography; the existing ground and water features; potential drainage outfalls; existing roads and infrastructure; properties, land/farm boundaries; and the environmental constraints identified during the DMRB Stage 2 Scheme Assessment Report.

Potential Impacts and Effects

Introduction

The construction of the proposed scheme will require the use of material assets which impacts upon their immediate and, in the case of primary aggregates, long-term availability, resulting in temporary or permanent adverse effects on the environment through the depletion of natural resources. Material assets include both primary materials, such as mineral aggregates, and manufactured construction products such as asphalt and concrete. Some of these materials would originate offsite, purchased as primary construction products, but some would arise onsite, particularly from the use of excavated soils, crushed concrete or recycled asphalt planings, or recycled materials brought in from offsite, possibly from other projects or industries.

The construction of the proposed scheme will also generate surplus materials and waste, leading to potential impacts on the available waste management infrastructure through permanently occupying landfill capacity. Landfill is a finite resource, and the successive disposal of waste generally results in a continued need to expand existing, and develop new, landfill facilities. This loss of resources to landfill generally requires the extraction or production of new material assets which, in turn, accelerates the depletion of natural resources, resulting in temporary or permanent adverse effects on the natural environment.

Embedded Mitigation

Throughout the DMRB Stage 3 iterative design process, a number of engineering, buildability and environmental workshops have considered each aspect of the developing design and made recommendations for certain features to be included in the next design iteration.

These aspects have been defined as ‘embedded mitigation’ and where they are incorporated into the proposed scheme, they are considered within the context of the impact assessment as providing mitigation to avoid or reduce potential environmental effects. These measures are detailed in Chapter 5 (Iterative Design Development) and Chapter 6 (The Proposed Scheme).

With respect to the material assets and waste elements under consideration in this chapter, it is important to note that the design iterations have been informed by ongoing consideration of earthworks materials balance across the proposed scheme. The main focus at DMRB Stage 3 has been to consider the various means of incorporating embedded mitigation through refining the proposed scheme alignment and levels to optimise the cut and fill balance.

Other specific opportunities identified at the time of assessment, with the potential to reduce materials consumption and waste generation, and which have been incorporated into the proposed scheme as embedded mitigation include, but are not limited to the following design development measures which are further detailed in the DMRB Stage 3 Assessment Report Volume 1 Part 2 Chapter 4 Engineering Assessment:

- General design development.

- Removal of a Roundabout at Dalguise Grade Separated Junction.

- Dalguise Vertical Alignment Redesign.

- Inver Parallel Access Track Removal.

- Murthly Estate Access Track Relocation.

- Design Development – Birnam Glen Bridge.

- Birnam Junction Bridge Structure Form.

Consumption and Use of Material Assets

The types of material assets likely to be required for construction are common to all road schemes. Indicative estimated quantities of the major materials required for the proposed scheme, including a 15% contingency to cover any unknown items, are as shown in Table 14.10.

Material assets consumption has been estimated through a review of the DMRB Stage 3 preliminary design information. Indicative levels of recycled content have been sourced thorough reference to material specific recycled content levels, at good practice levels, provided in the Net Waste Tool Dataset (WRAP, 2008).

Given the age of this data, good practice benchmarks, as opposed to standard or best practice benchmarks, have been selected in order to provide a reasonable and realistic worst case assessment scenario in line with WRAP following benchmark definitions:

- 'Standard practice' benchmarks reflect the baseline performance of the construction industry, at the time of publication, based on achieving minimum standards and legal requirements.

- 'Good practice' benchmarks reflect going beyond standard practice to realise 'quick win' - benefits that are easy to achieve on a majority of projects without a fundamental change in working practice and were at least cost neutral at the time of publication.

- 'Best practice' benchmarks reflect the leading approach undertaken in the industry at the time of publication, but may bear a cost premium or require a significant change in working practice on some projects.

The use of good practice benchmarks aligns with the implementation of those essential mitigation measures/targets identified in Section 14.5 (Mitigation) of this chapter. These measures would be implemented to reduce the use of new/virgin materials and increase the use of reused, recycled, recovered and responsibly sourced materials in the proposed scheme.

| Material assets | Approximate Quantity Range (t) | Indicative Recycled Content Levels (%) | Estimated Recycled Content Range (t) | Estimated Virgin Content Range (t) |

|---|---|---|---|---|

| Site-won general fill | 1,547,462 | 100 | 1,547,461.5 | 0.0 |